It is called both AM (additive manufacturing) or ALM (additive layer manufacturing).

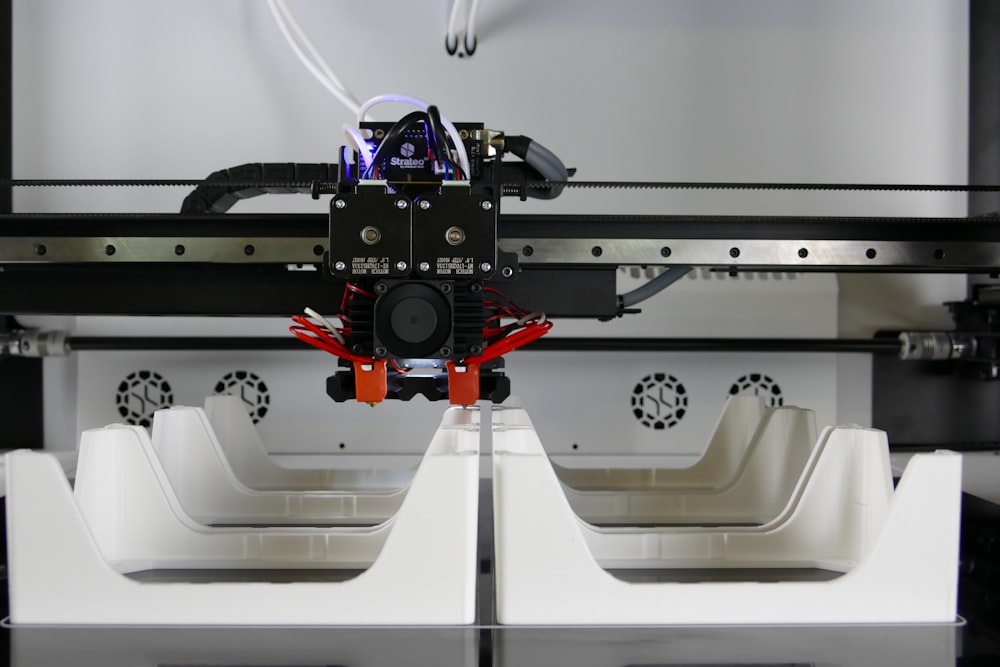

This is actually same as 3D printing but in industrial level.

Normally we produce material with machining or casting. In additive manufacturing we produce material layer by layer.

There are different methods for manufacturing like binder jetting, directed energy deposition, material extrusion, power bed fusion, sheet lamination, vat polymerisation, wire arc AM.

AM has less material wastage compared to machining method. Also ideal for rapid prototyping, reduces lead times. You can also combine parts that are normally not possible to produce in one.

AM has a quality x time balance. If you want higher quality you need to give more time, if you want to produce in less time, you will have less quality. Volume is another factor which you can’t play with. If material has higher volume you need to wait more.

Biochemicals, ceramics, metals and thermoplastics can be used as a raw material.

AM is used in aerospace, automotive and medical.