Continue reading TEA BREAK WITH NANOCAD: 2.4 SELECTING OBJECTS

Tag Archives: Engineering

BLOG: TECHNICAL OVERVIEW OF WATER TREATMENT: PROCESSES AND FORMULAS

Water treatment is a complex process that involves a variety of physical, chemical, and biological processes. In this blog post, we will explore the various methods and technologies used in water treatment, with a focus on the technical details and formulas involved.

Screening

The first step in water treatment is typically the screening process, which involves the removal of large debris and particles from the raw water source. This is typically done using a screen or mesh filter, which prevents large particles from entering the treatment system. The size of the screen or mesh filter is typically measured in terms of mesh size, which refers to the number of openings per inch. For example, a 200 mesh screen has 200 openings per inch.

Coagulation and Flocculation

The next step in water treatment is coagulation and flocculation, which involves adding chemicals to the water to create larger particles, called floc, which can be easily removed from the water. The two primary chemicals used in this process are aluminum sulfate (Al2(SO4)3) and ferric chloride (FeCl3).

The effectiveness of coagulation and flocculation can be quantified using the jar test, which involves mixing a small sample of water with various doses of coagulant and observing the resulting floc formation. The optimal dosage of coagulant can then be determined based on the best floc formation.

Sedimentation

After coagulation and flocculation, the water is sent through a sedimentation tank, where the floc settles to the bottom of the tank and is removed. The rate of sedimentation can be calculated using Stokes’ Law, which states that the rate of settling of a particle in a fluid is proportional to the particle’s radius, density, and the difference in density between the particle and the fluid. The formula for Stokes’ Law is:

$latex V = \frac{2}{9}\frac{(d_p – d_f)gr^2}{u} $

where V is the settling velocity, dp is the density of the particle, df is the density of the fluid, g is the acceleration due to gravity, r is the radius of the particle, and u is the viscosity of the fluid.

Filtration

After sedimentation, the water is sent through a series of filters to remove remaining impurities. The two primary types of filters used in water treatment are rapid sand filters and granular activated carbon (GAC) filters.

Rapid sand filters are typically composed of multiple layers of sand and gravel, with the largest particles at the bottom and the smallest particles at the top. As water passes through the filter, impurities are trapped in the sand and gravel layers. The effectiveness of a sand filter can be measured using the head loss method, which involves measuring the pressure drop across the filter as water flows through it.

GAC filters are composed of activated carbon particles, which have a large surface area and can adsorb a variety of organic and inorganic compounds from the water. The effectiveness of a GAC filter can be measured using the breakthrough curve method, which involves monitoring the concentration of a target compound in the filtered water over time.

Disinfection

After filtration, the water is disinfected to kill any remaining bacteria and viruses. The most common disinfectant used in water treatment is chlorine, which is added to the water in precise amounts to ensure the water is safe to drink. Chlorine works by reacting with the organic matter in the water and producing hypochlorous acid, which is a strong oxidizing agent that can kill bacteria and viruses.

The amount of chlorine needed to disinfect the water depends on the level of organic matter present in the water. The formula used to calculate the amount of chlorine needed is:

$latex C_t = \frac{V_s(C_i – C_f)}{V_wQ} $

where Ct is the target chlorine concentration, Vs is the volume of the water being treated, Ci is the initial chlorine concentration, Cf is the desired chlorine concentration, Vw is the volume of the water in the treatment tank, and Q is the flow rate of the water.

Once the chlorine has been added to the water, it is typically held in a contact tank for a period of time to ensure that all of the bacteria and viruses are killed. The contact time required varies depending on the level of organic matter in the water, but is typically around 30 minutes.

pH Adjustment

In addition to disinfection, the pH of the water may also need to be adjusted to ensure that it is safe for consumption. The optimal pH for drinking water is typically between 6.5 and 8.5. If the pH is too low or too high, it can cause corrosion of the pipes and other infrastructure, as well as impact the taste of the water.

The pH of the water can be adjusted using various chemicals, including sodium carbonate (Na2CO3) and sodium hydroxide (NaOH). The amount of chemical needed to adjust the pH depends on the initial pH of the water and the desired pH.

Conclusion

Water treatment is a critical process that ensures the safety and quality of our drinking water. The various steps involved in water treatment, including screening, coagulation and flocculation, sedimentation, filtration, disinfection, and pH adjustment, require a combination of physical, chemical, and biological processes. Understanding the technical details and formulas involved in these processes is crucial to developing effective water treatment systems that meet the needs of communities around the world.

BLOG: THE ESSENTIAL GUIDE TO ROPES IN ENGINEERING: TYPES, USES AND MANUFACTURING

Ropes are essential tools that have been used for centuries, and they are still widely used in engineering today. They are made up of fibers or wires that are twisted together to form a strong, flexible, and durable material that can be used for a wide range of applications. In this blog post, we will explore the different types of ropes, their uses in engineering, and how they are made.

Types of Ropes

There are several types of ropes, each with its unique characteristics and uses. Some of the most common types of ropes used in engineering include:

- Synthetic Ropes: These ropes are made from synthetic materials such as polyester, nylon, and polypropylene. They are lightweight, strong, and have excellent resistance to UV radiation and chemicals.

- Wire Ropes: Wire ropes are made from strands of steel wires twisted together. They are incredibly strong, durable, and have excellent resistance to abrasion and corrosion.

- Natural Fiber Ropes: Natural fiber ropes are made from materials such as hemp, sisal, and cotton. They are biodegradable, cost-effective, and have excellent grip characteristics.

Uses of Ropes in Engineering

Ropes have a wide range of uses in engineering, including:

- Lifting and Rigging: Ropes are commonly used in lifting and rigging applications, such as crane operations, hoists, and pulleys.

- Transportation: Ropes are used in transportation applications, such as mooring ships, towing vehicles, and securing cargo.

- Construction: Ropes are used in construction applications, such as scaffolding, safety lines, and bridge construction.

- Rescue Operations: Ropes are commonly used in rescue operations, such as in mountain climbing, search and rescue, and firefighting.

How Ropes are Made

The process of making ropes involves twisting fibers or wires together to create a strong, durable material. The specific method used to create ropes depends on the type of rope being made. For example, synthetic ropes are typically made by extruding synthetic fibers through a die to create a continuous strand that is then twisted together to form the final rope.

Conclusion

Ropes are an essential tool in engineering and have been used for centuries. They are made from a variety of materials, including synthetic fibers, steel wires, and natural fibers, and have a wide range of applications. Understanding the different types of ropes, their uses in engineering, and how they are made is essential for anyone working in the field of engineering.

BLOG: Revolutionizing Engineering: The Power of Artificial Intelligence

Artificial Intelligence (AI) is rapidly transforming the field of engineering, and its potential applications are virtually limitless. From automating tedious tasks to optimizing complex systems, AI is revolutionizing the way we approach engineering problems.

At its core, AI is all about developing algorithms that can learn from data and make predictions or decisions based on that data. This can be incredibly powerful in engineering, where we often deal with large amounts of data and complex systems that are difficult to optimize manually.

One of the most promising applications of AI in engineering is in the realm of predictive maintenance. By analyzing sensor data from machines and equipment, AI algorithms can identify patterns that indicate when maintenance is needed, allowing engineers to address potential issues before they become major problems. This can help to reduce downtime, improve reliability, and ultimately save money.

Another area where AI is making a big impact is in the design process. By using machine learning algorithms to analyze large datasets of design information, engineers can identify patterns and optimize designs more quickly and accurately than ever before. This can help to speed up the design process and improve the quality of the final product.

AI is also being used to optimize manufacturing processes, by identifying the most efficient ways to produce products and reducing waste. This can help to improve productivity and reduce costs, while also minimizing the environmental impact of manufacturing.

Of course, like any new technology, AI also presents some challenges and risks. One of the biggest concerns is the potential for bias in AI algorithms, which can lead to unintended consequences and unfair outcomes. As engineers, it’s important to be aware of these risks and work to mitigate them through careful design and testing.

Overall, the potential benefits of AI in engineering are enormous, and we’re only just scratching the surface of what’s possible. As the technology continues to evolve and improve, we can expect to see even more exciting developments in the years ahead.

BLOG: How Engineers are Using Augmented Reality to Transform the Construction Industry

As the construction industry continues to evolve, engineers are constantly exploring new technologies to help them design, plan, and execute projects more efficiently. One of the most exciting developments in recent years has been the emergence of augmented reality (AR) as a powerful tool for engineers in the construction industry.

AR technology allows engineers to overlay digital images and information on top of the real-world environment, providing them with a highly detailed, 3D view of a construction site or building. This technology has the potential to transform the way engineers work, improving accuracy, efficiency, and safety on construction sites.

Here are just a few of the ways engineers are using AR technology to transform the construction industry:

- Improved Design Visualization: With AR technology, engineers can create highly realistic 3D models of buildings and construction sites. This allows them to get a better sense of how a project will look in the real world, and make adjustments before construction even begins. By visualizing a project in detail before construction, engineers can identify and address potential issues early on, saving time and money in the long run.

- Enhanced Collaboration: AR technology also makes it easier for engineers to collaborate with other professionals involved in a project, such as architects, contractors, and project managers. By sharing a common digital platform, everyone can see the same 3D models and annotations, making it easier to communicate ideas and solve problems together.

- Safer Work Environments: One of the most important benefits of AR technology is that it can improve safety on construction sites. By providing engineers with a 3D model of a construction site, they can identify potential hazards and design solutions to minimize risk. AR technology can also be used to provide training simulations for workers, helping them to learn the necessary skills and safety protocols in a safe, virtual environment.

- More Efficient Project Management: AR technology can also improve the efficiency of project management. By providing a detailed, 3D model of a construction site, engineers can create accurate schedules and cost estimates. They can also use the technology to monitor progress and identify potential delays or bottlenecks, allowing them to adjust the project plan as needed to keep everything on track.

In conclusion, augmented reality technology is quickly becoming a game-changer for engineers in the construction industry. By providing a highly detailed, 3D view of construction sites and buildings, AR technology can improve accuracy, efficiency, and safety, while also making it easier for engineers to collaborate and manage projects. As this technology continues to evolve, we can expect to see even more innovative uses in the construction industry in the years to come.

BLOG: The Future of Renewable Energy: Latest Developments in Engineering

The world is shifting towards renewable energy sources as the impact of climate change becomes increasingly evident. Engineers are playing a vital role in this transition, developing new technologies and making existing ones more efficient. In this blog post, we will take a closer look at the latest developments in engineering related to renewable energy, and what they mean for the future.

- Solar Energy: Solar energy is one of the most promising renewable energy sources, and engineers are constantly working on making it more efficient and affordable. One of the latest developments in this field is the use of perovskite solar cells, which are cheaper and more efficient than traditional silicon-based cells. Perovskite solar cells are still in the early stages of development, but they have the potential to revolutionize the solar industry.

- Wind Energy: Wind turbines are a common sight in many parts of the world, and engineers are working on making them more efficient and reliable. One of the latest developments in this field is the use of vertical axis wind turbines (VAWTs), which are smaller and more suitable for urban areas than traditional horizontal axis wind turbines (HAWTs). VAWTs are also less prone to damage from extreme weather conditions, making them a more sustainable option for areas prone to hurricanes and tornadoes.

- Hydrogen Fuel Cells: Hydrogen fuel cells are another promising renewable energy source, and engineers are working on making them more affordable and practical. One of the latest developments in this field is the use of proton exchange membrane (PEM) fuel cells, which are more efficient and durable than traditional alkaline fuel cells. PEM fuel cells are also smaller and lighter, making them suitable for use in cars and other vehicles.

- Energy Storage: Energy storage is a crucial component of any renewable energy system, as it allows for the storage of excess energy generated during peak periods. Engineers are working on developing new energy storage technologies, such as lithium-ion batteries and flow batteries, that are more efficient and cost-effective than traditional lead-acid batteries.

In conclusion, renewable energy is the future, and engineers are playing a vital role in making it a reality. By developing new technologies and making existing ones more efficient, engineers are helping to create a more sustainable and resilient energy system for the future. If you are interested in learning more about the latest developments in engineering related to renewable energy, be sure to follow our blog for more updates and insights.

BLOG: The Future of Engineering: Trends to Watch Out For

As technology continues to advance, the field of engineering is evolving at an incredible pace. From new materials to innovative construction techniques, there are a lot of exciting trends to keep an eye on. In this post, we’ll explore some of the top engineering trends that are shaping the future of the industry.

- Sustainable Engineering: With a growing concern for the environment, sustainable engineering has become an important focus for many engineers. From designing green buildings to creating more efficient transportation systems, engineers are finding new ways to reduce the impact of human activity on the planet.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML are transforming the way engineers work. By analyzing large amounts of data, these technologies can help engineers identify patterns and make predictions that were previously impossible. They can also automate tedious tasks, freeing up more time for engineers to focus on complex problem-solving.

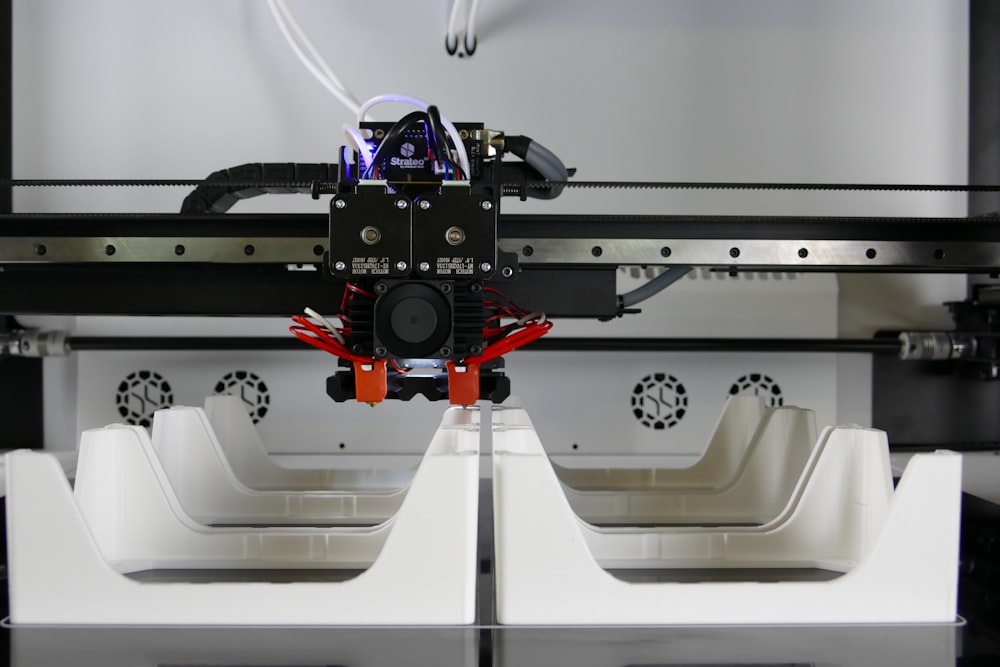

- Additive Manufacturing: 3D printing and other forms of additive manufacturing are revolutionizing the way products are designed and produced. With the ability to quickly create prototypes and customize products, engineers are able to bring their ideas to life faster than ever before.

- Internet of Things (IoT): The IoT refers to the network of physical devices that are connected to the internet, allowing them to exchange data and communicate with each other. In engineering, the IoT is being used to create smart buildings and infrastructure that can monitor and optimize energy usage, among other things.

- Advanced Materials: New materials are being developed that are stronger, lighter, and more durable than ever before. From self-healing concrete to graphene-based materials, engineers are constantly pushing the boundaries of what is possible.

As these trends continue to develop, the future of engineering looks brighter than ever. By staying up-to-date with the latest developments, engineers can stay ahead of the curve and continue to make a positive impact on the world.

EE29: MOTOR CURRENT CALCULATOR

ME18: PIPE SCHEDULES WALL THICKNESS

Dimensions are in inches.

| NPS | 5s | 5 | 10s | 10 | 20 | 30 | 40s STD | 40 |

| 1/8 | .035 | .049 | .049 | .068 | .068 | |||

| 1/4 | .049 | .065 | .065 | .088 | .088 | |||

| 3/8 | .049 | .065 | .065 | .091 | .091 | |||

| 1/2 | .065 | .065 | .083 | .083 | .109 | .109 | ||

| 3/4 | .065 | .065 | .083 | .083 | .113 | .113 | ||

| 1 | .065 | .065 | .109 | .109 | .133 | .133 | ||

| 1 1/4 | .065 | .065 | .109 | .109 | .140 | .140 | ||

| 1 1/2 | .065 | .065 | .109 | .109 | .145 | .145 | ||

| 2 | .065 | .065 | .109 | .109 | .154 | .154 | ||

| 2 1/2 | .083 | .083 | .120 | .120 | .203 | .203 | ||

| 3 | .083 | .083 | .120 | .120 | .216 | .216 | ||

| 3 1/2 | .083 | .083 | .120 | .120 | .226 | .226 | ||

| 4 | .083 | .083 | .120 | .120 | .237 | .237 | ||

| 4 1/2 | .247 | |||||||

| 5 | .109 | .109 | .134 | .134 | .258 | .258 | ||

| 6 | .109 | .109 | .134 | .134 | .280 | .280 | ||

| 7 | .301 | |||||||

| 8 | .109 | .109 | .148 | .148 | .250 | .277 | .322 | .322 |

| 9 | .342 | |||||||

| 10 | .134 | .134 | .165 | .165 | .250 | .307 | .365 | .365 |

| 11 | .375 | |||||||

| 12 | .156 | .165 | .180 | .180 | .250 | .330 | .375 | .406 |

| 14 | .156 | .188 | .250 | .312 | .375 | .375 | .437 | |

| 16 | .165 | .188 | .250 | .312 | .375 | .375 | .500 | |

| 18 | .165 | .188 | .250 | .312 | .437 | .375 | .562 | |

| 20 | .188 | .218 | .250 | .375 | .500 | .375 | .593 | |

| 24 | .218 | .250 | .250 | .375 | .562 | .375 | .687 | |

| 26 | .312 | .500 | .375 | |||||

| 28 | .312 | .500 | .625 | .375 | ||||

| 30 | .250 | .312 | .312 | .500 | .625 | .375 | ||

| 32 | .312 | .500 | .625 | .375 | .688 | |||

| 34 | .312 | .500 | .625 | .375 | .688 | |||

| 36 | .312 | .625 | .375 | .750 | ||||

| 42 | .375 | |||||||

| 48 | .375 |

| NPS | 60 | 80s E.H. | 80 | 100 | 120 | 140 | 160 | Dbl. E.H. |

| 1/8 | .095 | .095 | ||||||

| 1/4 | .119 | .119 | ||||||

| 3/8 | .126 | .126 | ||||||

| 1/2 | .147 | .147 | .187 | .294 | ||||

| 3/4 | .154 | .154 | .218 | .308 | ||||

| 1 | .179 | .179 | .250 | .358 | ||||

| 1 1/4 | .191 | ..191 | .250 | .382 | ||||

| 1 1/2 | .200 | .200 | .281 | .400 | ||||

| 2 | .218 | .218 | .343 | .436 | ||||

| 2 1/2 | .276 | .276 | .375 | .552 | ||||

| 3 | .300 | .300 | .437 | .600 | ||||

| 3 1/2 | .318 | .318 | .636 | |||||

| 4 | .281 | .337 | .337 | .437 | .531 | .674 | ||

| 4 1/2 | .355 | .710 | ||||||

| 5 | .375 | .375 | .500 | .625 | .750 | |||

| 6 | .432 | .432 | .562 | .718 | .864 | |||

| 7 | .500 | .875 | ||||||

| 8 | .406 | .500 | .500 | .593 | .718 | .812 | .906 | .875 |

| 9 | .500 | |||||||

| 10 | .500 | .500 | .593 | .718 | .843 | 1 | 1.125 | |

| 11 | .500 | |||||||

| 12 | .562 | .500 | .687 | .843 | 1 | 1.125 | 1.312 | |

| 14 | .593 | .500 | .750 | .937 | 1.093 | 1.250 | 1.406 | |

| 16 | .656 | .500 | .843 | 1.031 | 1.218 | 1.437 | 1.593 | |

| 18 | .750 | .500 | .937 | 1.156 | 1.375 | 1.562 | 1.781 | |

| 20 | .812 | .500 | 1.031 | 1.280 | 1.5 | 1.750 | 1.968 | |

| 24 | .968 | .500 | 1.218 | 1.531 | 1.812 | 2.062 | 2.343 | |

| 26 | .500 | |||||||

| 28 | ||||||||

| 30 | .500 | |||||||

| 32 | .500 | |||||||

| 34 | ||||||||

| 36 | .500 | |||||||

| 42 | .500 | |||||||

| 48 | .500 |

E.H.: extra heavy

Dbl: double